INDUSTRIAL & OEM

FASTENERS

SEALING WASHERS

METAL BACKING MATERIAL & FACING MATERIAL DESCRIPTIONS

Leland Industries assembled fastener products are produced utilizing the highest quality sealing washers.

FLOW CONE WASHERS,

US Patent #4292876

Flow cone washers are assembled primarily on the Master Gripper family of fasteners.

Vulcanized Grey or Black EPDM to special dished dome galvanized washers.

Vulcanized Grey or Black EPDM flows up into the cone shaped washer to seal around screw threads, fastener shank and under head providing a complete seal.

MASTER SEAL WASHERS

Master Seal Washers are assembled to a wide range of Leland fasteners.

The most common Master Seal Washer is produced with a Galvanized metal washer vulcanized to an EPDM sealing washer.

EPDM ( Ethylene Propylene Diene Monomer ) provides most economical, high quality sealing material. Ozone and weather resistant elastomer with superior aging characteristics.

Heat resistant to 350°F.

ALTERNATE BACKING MATERIALS

ALUMINUM

Provides special alloys that provide similiar longevity to galvanized when low stress or desired deflection requirements exist.

Aluminum minimizes concerns with galvanic corrosion in certain applications.

STAINLESS STEEL (300 SERIES 18/8)

Combines optimum corrosion resistance and economy in a premium quality washer. Used wherever stainless steel fasteners are required or when corrosive environments compromise lesser metals.

ALTERNATE FACING MATERIALS AVAILABLE

NEOPRENE

Versatile general duty facing material for sealing and cushioning washers.

Highly resistant to petro chemicals and certain other chemical families.

SILICONE

High performance – economical, working temperature extremes from -115°F to +480°F.

Highly resistant to chemical environments and repeated sterilization.

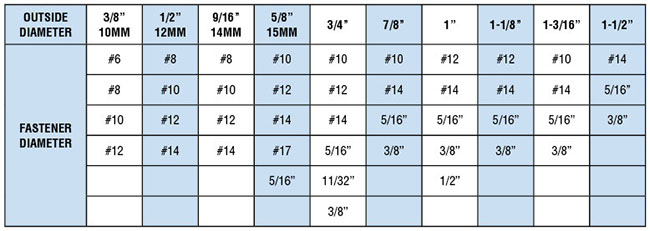

MASTER SEAL BONDED WASHER DIAMETER & FASTENER DIAMETER CHART