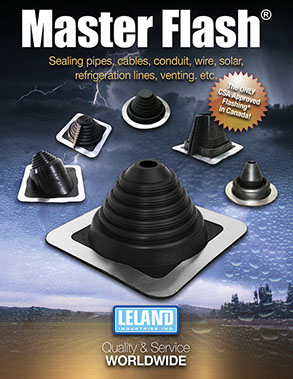

MASTER FLASH®

QUALITY & SERVICE WORLDWIDE

Design Excellence

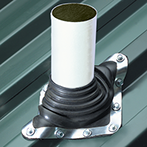

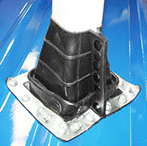

Master Flash® design meets all roofing needs. Sleeve flexibility accommodates vibration and pipe movement caused by expansion contraction. The soft aluminum base easily conforms to most metal roof profiles.

Weather Protection

Made or EPDM, these flashings are compounded specifically for maximum resistance to weathering due to ozone and ultraviolet light.

Base Flexibility

The base is designed to form a seal on most panel configurations and roof pitches regardless of pipe location.

Easy On-Site Customization

Fast, one piece construction allows for easy on-site installation usually 5 minutes.

Modification Made Simple

Easy to see pipe diameters make for painless on-site installation.

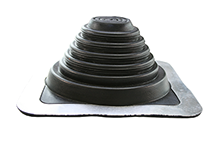

Standard Master Flash®

- 9 sizes, designed for 1/4” to 28-1/2” (6 – 723mm) diameter pipes

- Easy on-site installation in usually 5 minutes

- The soft aluminum base easily conforms to most metal roof profiles

- Pipe diameters can be seen clearly for proper pipe fitting

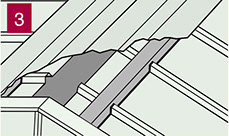

Extreme Angle Master Flash®

- Designed for 1/4” to 5-3/4” (6 – 146mm) diameter pipes

- Easy on-site installation in usually 5 minutes

- The built in 40º degree pitch allows to handle any extreme roof pitch (35º – 65º)

- Sleeve flexibility accommodates vibration and pipe movement caused by expansion contraction

Multi-Flash Master Flash® Two Flashings in ONE!

- 9 Sizes, designed for 1/4” to 28-1/2” (6 – 723mm) diameter pipes

- Smooth cut is intended to eliminate use of razor blades

- Stainless steel gripper to secure a retro custom fit

- Gripper available upon request

Retrofit Master Flash®

- 3 sizes, designed for 1/2” to 16-1/4” (12 – 412mm) diameter pipes

- Easy to see pipe diameters make for painless on site customization

- Easily installed fastener snaps included

Solar Multi-Port - MR Master Flash®

5 Port Design for the Metal Roofing Industry

• Accommodates:

ONE 0” – 1-15/16” (0 – 49mm) pipe

TWO 3/8” (9.6mm) pipe / cable

TWO 3/4” (20mm) pipe / cable

- 4-1/2” (114mm) base

- Up to 4 cables or wires per flashing

- Extra ports to accommodate copper pipe and electrical cabling

- Easy install for solar applications

Square Vent Master Flash®

- 2 sizes/EPDM/designed for 2-1/2” to 5” (63 – 127mm) diameter pipes

- Made to withstand the damaging effects of ultraviolet light and ozone

- Easy install snaps included, specially designed for square vent applications

- Sleeve flexibility accommodates vibration and pipe movement caused by expansion/contraction

Universal Master Flash®

- All around performance

- 9 sizes, designed for 1/4” to 19” (6 – 482mm) diameter pipes

- Easy on-site customization can accommodate all normal installations

Solar-Flash Master Flash®

- Specifically designed for solar applications

- Designed for 3/4” (19mm) to 1” (25mm) diameter pipes

- Pre-cut hole for pipe sizes 3/4” (19mm) to 1” (25mm) allowing for minimal on-site preparation and assembly

- The pitch canal allows for maximum flexibility, easily accommodating up to a 60º degree pitch without affecting performance

Universal Retrofit Master Flash®

- 3 sizes, designed for 3/4” (19mm) to 10” (254mm) diameter pipes

- Fast, one piece construction allows for easy on-site install in usually 5 minutes

* Master Flash; the only CSA Approved EPDM rubber flashing.

The only ICC listed flashing for the Metal Building Industry with a 35 year warranty

- 11 Sizes / Designed for 1/8” to 28-1/2” (3-723mm) diameter pipes

- On-site customization

- Designed for 1/4” to 13” (6-330mm) diameter pipes

- Pipe diameters can be seen clearly for proper pipe fitting

MASTER CLOSURE

A SUPERIOR METAL PANEL & METAL ROOF CLOSURE SYSTEM

- Master Closure is a non shrinking crosslink polyethylene foam, 2 lb. density, charcoal gray in color

- Fast, easy and economical to install in lengths to fit your profile

- Available with or without glue bead for easy installation

- Most metal profiles are available and in stock

- Configurations for outside and inside metal profiles

- Provides complete snow, rain and insect barrier

- No special tools required – simply peel and stick

- Very light weight product that is easily handled and installed

- Does not promote combustion

Technical Data:

MASTER CLOSURE PHYSICAL SPECIFICATIONS

Density: 2 pcf – no shrinkage

Elongation: 120% (% to break)

Compression set: 28% (% original thickness)

Water absorption: 0.04 – lb/sq ft

(Does not absorb water)

Tensile strength: 43 psi

Tear resistance: 11 – lbs/in2

Shore hardness (A): 7

Working temperature: -70°F to +175°F

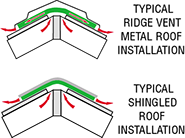

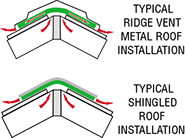

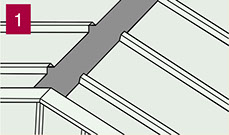

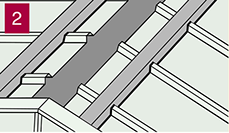

MASTER RIDGE VENT

A Superior Metal Panel & Metal Roof Closure System

- Available in 8” x 20 foot or 11.5” inch X 20 foot rolls

- No special tools required – simply fasten with nails included

- Joints are square cut for excellent fit

- Net free area of air exhaust is 22 square inches per linear foot

- Conforms to any roof pitch from 2/12 to 20/12

- Provides excellent snow, rain and insect barrier

- Invisible ridge ventilation from ground level

- Use your standard metal or fiberglass ridge cap

- Use 2”, 2-1/2” or 3” Master Grippers to install all ridge caps

- Does not promote combustion

Technical Data:

MASTER RIDGE VENT PHYSICAL SPECIFICATIONS

Water absorption : Does not absorb water

Cold cracking resistance: Tested at -20°F – exposure period – 6 hours

No breakage of fibers

Working temperature range: 40°F to 180°F

Self ignition temperature: 970°F

Dust flow rate 4: 6 gm./min. @ 15 M.P.H. wind speed

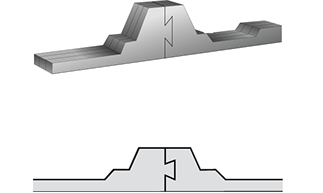

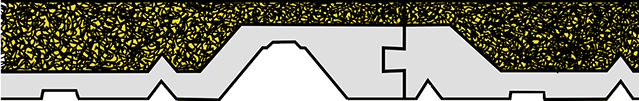

MASTER VENTED CLOSURE

VENTED CLOSURE can be cut with a knife or scissors. When joining VENTED CLOSURE simply slide the tongue and groove together for a perfect, air tight fit.

The Ultimate Vented Closure, Uniquely Designed for the Commercial & Residential Metal Roofing Industry

- Superior roof ridge venting

- Minimal penetration from wind driven rain. Features interlocking dovetail joints

- One person installation. No tools required

- Supplied in 36” lengths, peel and stick glue bead

- Excellent snow, rain, insect barrier, mold resistant

- Resistant to weathering and chemicals, won’t support flame

- UV stabilized and ozone resistant

- Low air resistance, 97% void volume

MASTER VENTED CLOSURE PHYSICAL SPECIFICATIONS

- Manufactured from 1.5” thick cross linked, closed cell polyethlene 2 lb. density. Assembled to 2” venting material.

- Net free area 16.56 sq.in. per 36” profile.

- Tear strength 11 lb. in.

- Elongation 120% to break.

- Tensile strength 43 P.S.I.

- Working temperature -40°F to +175°F.

Fasten metal ridge cap with Master Grippers and fibreglass reinforced plastic ridge cap with Master One Steppers.